Success Stories

SKA Robotics offers services in hardware, software, and systems engineering for a multitude of commercial and industrial robots. These success stories highlight some of the work we are particularly proud of.

AUTONOMY FOR MINING AND CONSTRUCTION VEHICLES

Stock image used to protect client confidentiality

SKA Robotics has assisted in the automation of multiple construction and mining vehicles across multiple brands ranging in working weight from under 500 pounds to more than 1,500,000 tons.

Our vehicle-mounted electronics packages enable the connection of sensors and compute for robotic autonomy and navigation to existing vehicles, enabling collision avoidance, autonomous navigation, and other types of autonomous operations. Our expertise in robot autonomy positions us to then implement these features.

These retrofits reduce operator error, increase efficiency, and take operators out of dangerous situations.

MULTI-ROBOT SOLAR FIELD CONSTRUCTION SYSTEM

Stock image used to protect client confidentiality

SKA Robotics contributed systems engineering and perception engineering expertise to a program designed to automate the construction of multi-square mile solar fields using multiple types of robots and fleet management.

On the systems engineering side, SKA maintained requirements, synthesized physical architectures, came up with a functional architecture for the system, and developed action diagrams for all states and modes of the various subsystems.

On the perception engineering side, SKA assisted in developing algorithms for the classification and localization of solar panels across a range of lighting conditions using multiple sensing and data processing modalities.

RUCKTRO UNMANNED GROUND VEHICLE

This experimental robot built by SKA utilizes a custom tank-style drivetrain. It can tow or mount 300 lbs. of payload and traverse pavement, snow, mud, dirt, and more. This modular machine can be quickly modified to perform a diverse array of tasks.

To ensure further reliability, SKA’s RuckTro unmanned ground vehicle is engineered to be resistant to moisture, heat, vibration, and debris. It can operate autonomously, remote-controlled, or manned.

The vehicle can drive upside-down with accessories and sensors removed, increasing its probability of mission success in scenarios when top-mounted equipment is not required.

Among other SKA-developed subsystems, including its drivetrain, batteries, power distribution harness, sensor enclosures and autonomy software, RuckTro features an ultra-compact power converter and distribution module (see below).

ULTRA-COMPACT POWER CONVERTER AND DISTRIBUTION MODULE

These compact boards are designed to provide stable power in a compact package. These are high-performance boards designed to live inside SKA products, such as RuckTro.

Specifications:

25mm x 75mm footprint

12 individually protected outputs on 2-pin Molex SL locking connectors

3 amps total output at 5 VDC

18 to 75V input (lab-tested by SKA up to 60V) on 2-pin Molex SL locking connector

On-board fuse and other input-side filtering + protections

AUTONOMOUS BLAST HOLE DRILLER

Stock image used to protect client confidentiality

An international manufacturer of construction and mining vehicles wanted to develop autonomous navigation for a new blast hole driller.

After assisting in building a 12th scale miniature of the vehicle for test and development purposes, SKA created navigational software using GPS information as an input.

The software enabled the vehicle to use waypoint navigation autonomously move to each hole location, drill blast holes, and geotag the holes, all while keeping human operators at a safe distance.

An autonomy kit based on the work done with miniatures, was integrated onto the full scale vehicle.

SOFTWARE SYSTEM FOR SURGICAL ROBOT

Stock image used to protect client confidentiality

Our client was in the process of building a surgical robot that could be teleoperated and needed a team that could quickly develop software to detect and proactively mitigate collisions with out-of-bounds areas during remote surgery as well as snap a surgical implement to precise tool paths in order to enable a surgeon to conduct operations that would not be feasible using a hand tool.

In order to accomplish this objective, a 7-person team spent two and a half months creating embedded software that was optimized to run on a low-level chipset including an STL parser, custom collision detection and mitigation algorithms, and interfaces to the rest of the client’s stack.

Since our module was built in tandem with the hardware itself, SKA built and maintained a software simulator / visualizer that was used for demonstrations and internal development and a test suite that was used to conduct quality assurance throughout the project. The client was very happy with SKA’s delivered code and maintained derivative work throughout the life of the program.

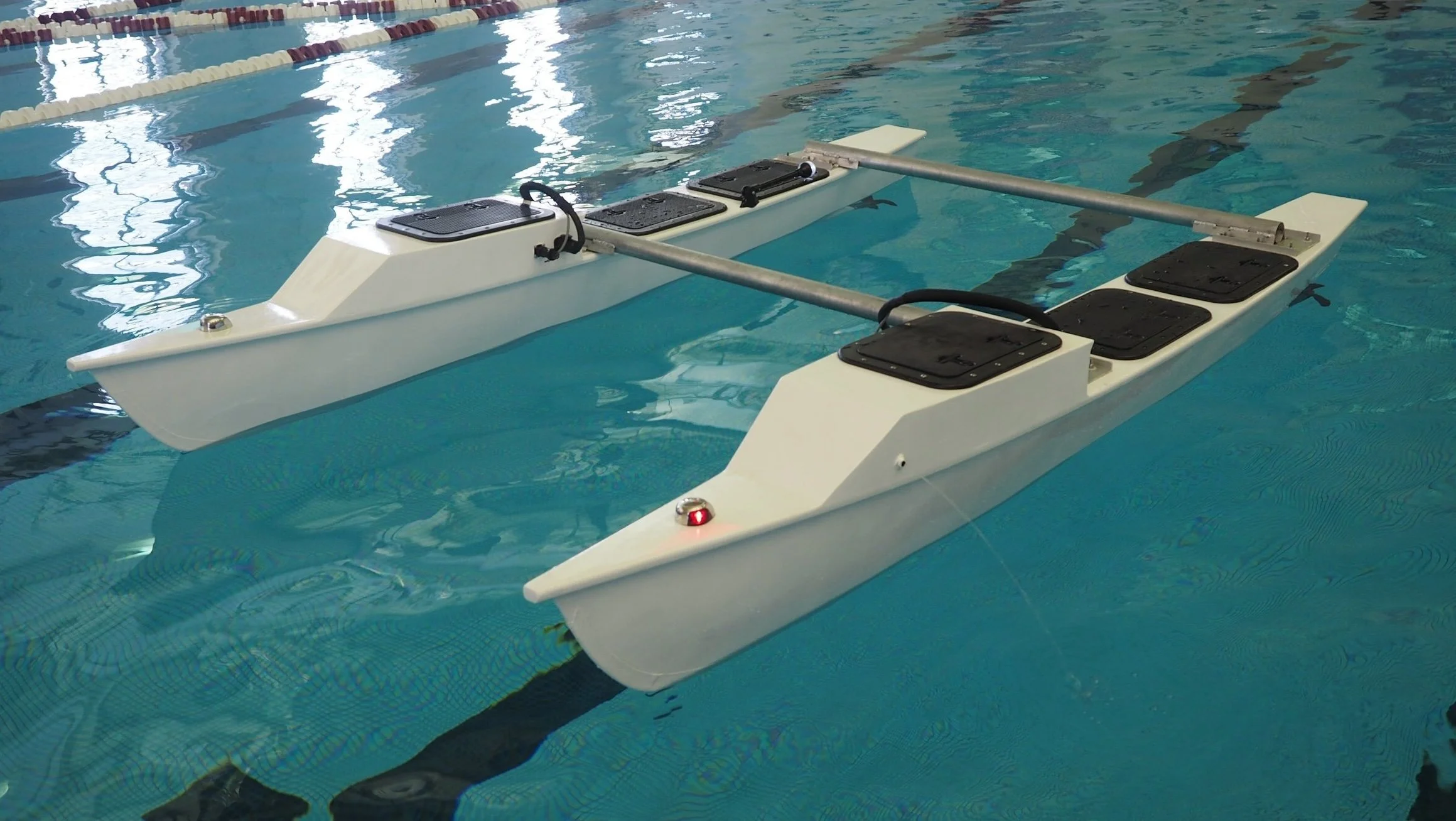

ROBOTIC CATAMARAN

Our client wanted to develop a catamaran that could autonomously collect water samples in the Gulf of Mexico.

SKA designed and fabricated the boat’s hulls and drive systems. The boat is 10 feet long and made from stainless steel, aluminum, fiberglass, and Kevlar. Partially flooded brushless drive systems allow the craft to zip along the water while eliminating the need for seals.

The catamaran has since been used to take water samples in the United States, Europe, and the Middle East.